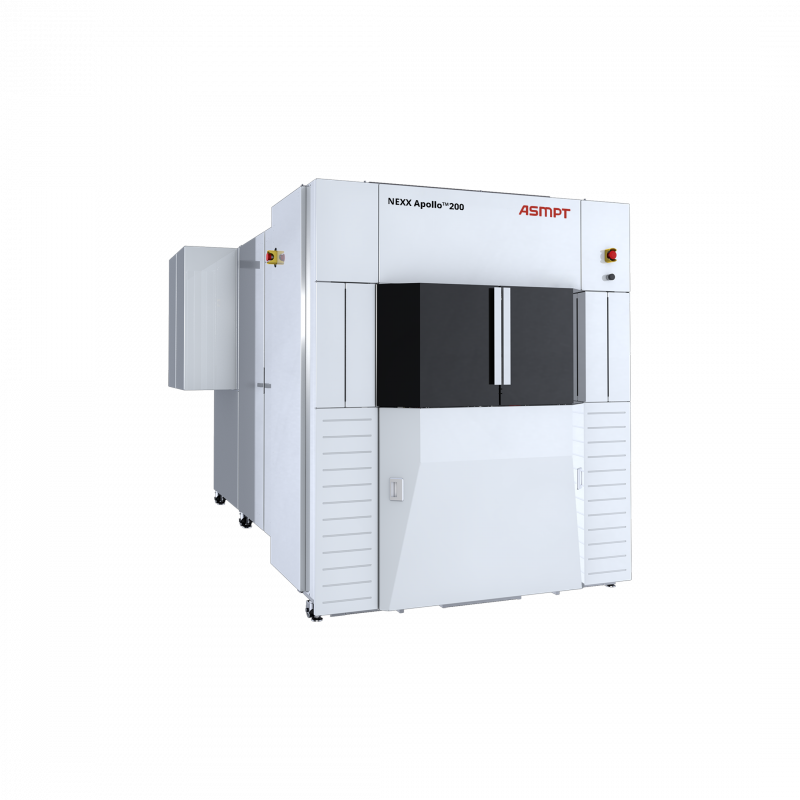

Apollo 200

StratusTM S200

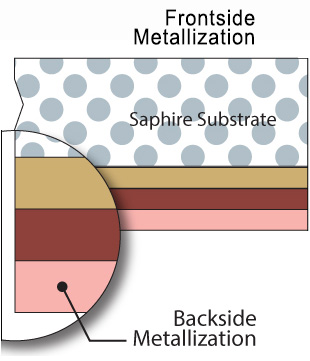

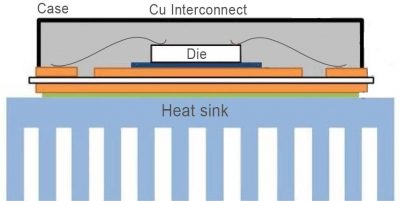

The networking and communications developments required to build the 5G communication infrastructure are driving a significant increase in power device production. Larger and larger power loads are being placed on different parts of the system and power electronics suppliers are responding with thermal management solutions that can meet these more stringent requirements. Higher thermal management capabilities are critical and devices must be more efficient to handle the loads, while also delivering these solutions in more compact systems. Manufacturers are turning wide band gap materials like SiC and GaN because of they thermal capabilities are more efficient than standard silicon. However, these wafers are very fragile and their production is in tight demand. Power innovators require tools that can handle these fragile wafers as well as manage the stress that is created when these wafers are plated and sputtered.

Product Offering

ASMPT NEXX offers sputtering and plating wafer level and plating panel level solutions dedicated to the processes that support power device manufacturing. NEXX serves the both the high volume and research and development needs of power devices makers.

Wafer Sputtering – Apollo 200

Apollo 200 has the flexibility to sputter thin or thick metal film using trays to protect fragile wafers. This sputtering tool deposits films increase the overall thermal rating of a package, as well as provide low resistance connectivity.

Benefits

- Safer handling of an array of fragile wafer types

- Film stress management

- Minimizing post process wafer bow

- High throughput sputtering solution for thick and thin films

- Handles multiple wafer sizes

- Up to 5 different metals

- Degas

- Anneal

- DC Pulsed Sputtering

- Backside Gas (BSG)

- Reactive Sputtering

- RF Bias

- ICP and CCP etch Electrostatic chucks

- Bridge tool capability

- Fully configurable

- Processes 200, 150, and 100 mm wafers

Wafer Plating – StratusTM S200

For customers who manufacture multiple advanced packaging features, including a variety of multimetal interconnects, the S200’s high speed wafer handling system delivers the flexibility and extendibility to produce both large and small features.

- Safer handling of thin, bowed and warped wafers

- Highest productivity plating tool on the market

- Process RDLs, Copper Pillars in one tool

- Handles multiple wafer sizes

- Shields make faster plating possible while maintaining good within wafer uniformity

- Up to 6 different chemistries

- Various reservoir sizes for high or low volume plating ShearPlate Technology

- Power supply flexibility

- Up to 20 wafer processing

- Bridge tool capability

- Fully configurable

- Processes 200, 150, and 100 mm wafers

Source: Ph.D. Thesis, 2015

Source: Ph.D. Thesis, 2015