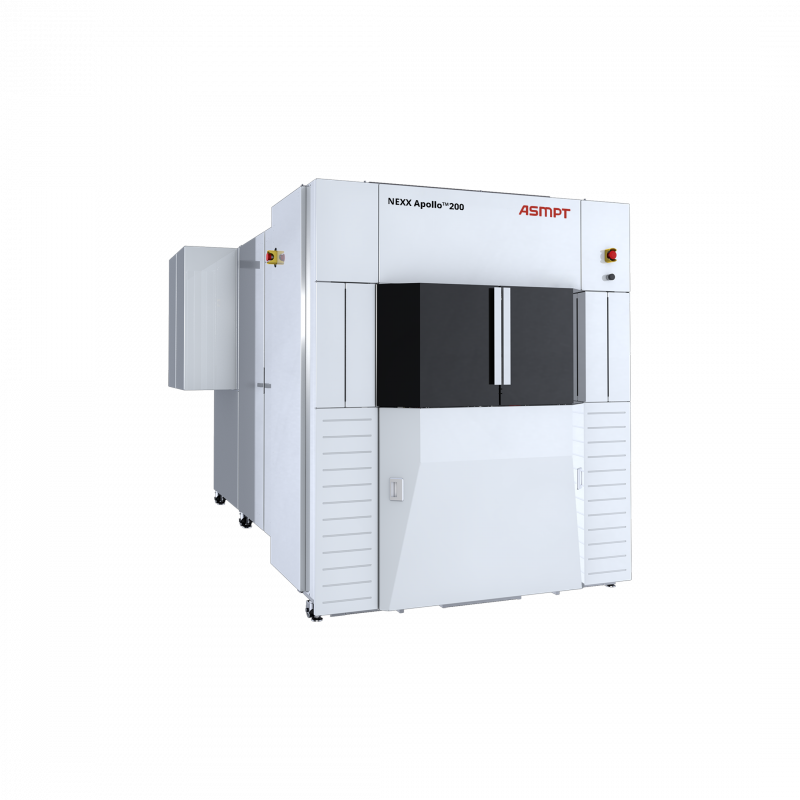

Apollo 200

StratusTM S200

As mobile handsets reach a greater portion of the earth’s population, the need for radio spectrums to communicate these devices to one another has skyrocketed. Five bands at the turn of the century has increased to more than 30 as we approach the 5G communication standard slated for 2020. Radio frequency (RF) front end modules and filters are key components to enabling 5G networks as 5G communication protocols are defined and implemented. RF and microwave filters represent a class of electronic filter, designed to operate on signals in the megahertz to gigahertz frequency ranges (medium frequency to extremely high frequency).

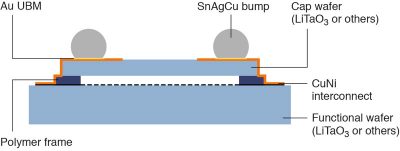

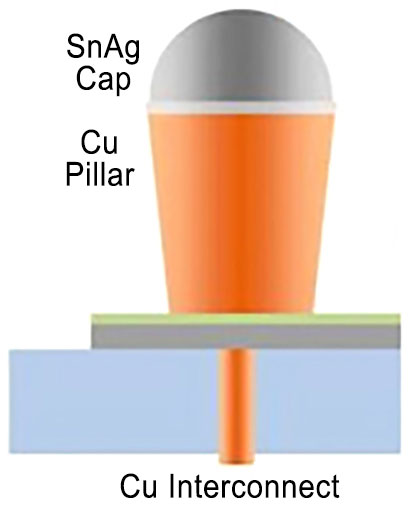

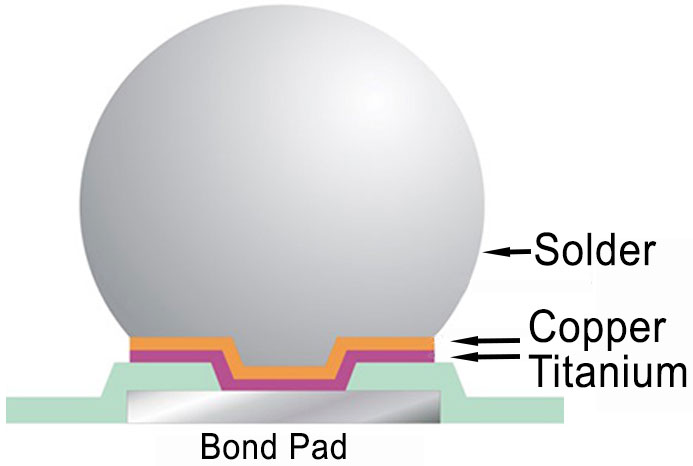

Acoustic wave technology, such as the popular Surface Acoustic Wave filter (SAW) and the higher technology Bulk Acoustic Wave (BAW) filter for more challenging interference environments, deliver interdigital transducers (IDTs) that provide some of the highest performance, smallest and lowest-cost filters in analog RF communication. Different filters trap acoustic energy in different ways. Manufacturers are increasingly coupling filters with amplifiers or an array of other devices to achieve even smaller form factors and higher functionality in the end package. The challenge for filter manufacturers is to safely plate and sputter metals on a variety of very fragile, small wafer sizes.

Product Offering

ASMPT NEXX offers sputtering and plating wafer and plating panel level solutions for the RF Filters processes. NEXX offers features and options to support both current processes and variations which evolve as the interconnection market matures. process matures. NEXX serves the high volume manufacturing portion of the RF Filters market.

Wafer Sputtering – Apollo 200

Apollo 200 has the flexibility to sputter thin or thick metal film using trays to protect fragile wafers. This sputtering tool deposits films increase the overall thermal rating of a package, as well as provide low resistance connectivity.

- Safer handling of an array of fragile wafer types

- Film stress management

- Minimizing post process wafer bow

- High throughput sputtering solution for thick and thin films

- Handles multiple wafer sizes

- Up to 5 different metals

- Degas

- Anneal

- DC Pulsed Sputtering

- Backside Gas (BSG)

- Reactive Sputtering

- RF Bias

- ICP and CCP etch Electrostatic chucks

- Bridge tool capability

- Fully configurable

- Processes 200, 150, and 100 mm wafers

Wafer Plating – StratusTM S200

For customers who manufacture multiple advanced packaging features, including a variety of multimetal interconnects, the S200’s high speed wafer handling system delivers the flexibility and extendibility to produce both large and small features.

- Safer handling of thin, bowed and warped wafers

- Highest productivity plating tool on the market

- Process RDLs, Copper Pillars in one tool

- Handles multiple wafer sizes

- Shields make faster plating possible while maintaining good within wafer uniformity

- Up to 6 different chemistries

- Various reservoir sizes for high or low volume plating ShearPlate Technology

- Power supply flexibility

- Up to 20 wafer processing

- Bridge tool capability

- Fully configurable

- Processes 200, 150, and 100 mm wafers